About evo's Seattle Ski and Snowboard Tuning, Waxing, Binding Mounting & Repairs:

If you are in the Seattle area you can bring your gear into our Seattle store to get it worked on. Below is a list of the services we offer and prices. Give us a call at (206) 973-4470 or just stop on by with your gear. We usually turn gear around super fast but depending on the time of year service levels fluctuate. As the leaves begin to change color and fall... thoughts of a cold powdery winter begin to saturate our minds. These thoughts take over all of our actions, and we become obsessed with preparing for winter. It’s time to think about getting ready to go into the mountains. All of us at the evo service shop understand these needs. We are ready to prep your skis and snowboards for the long powder filled days or grey-bird groomers. Located in the basement of evo’s flagship store in Seattle, our crew is in full swing tuning and waxing for the coming season.

As an evo tech, I love to see the excitement people have when I give them their gear, all ready to ride, knowing that I’m getting another person in the mountains to enjoy their passion...the snow. - Kinsey Smith, Seattle Service Shop Supervisor |

Our Machines:

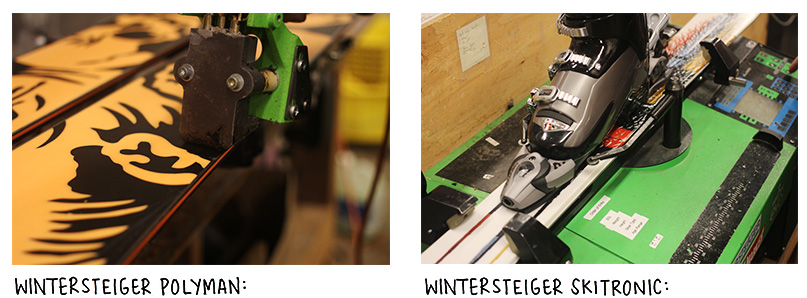

evo's Seattle store takes pride in every piece of equipment we work on. The tunes and mounts are all done by hand with the assistance of our Wintersteiger machines, which include: Wintersteiger Micro 90 to flatten and structure skis, Trim Disc to sharpen and polish edges, Polyman to fill scratches, a Skitronic to test bindings, and a Wax Jet to put a fresh coat of wax on freshly mounted skis. |

| |

| This beast has three functions; it flattens the ski or snowboard, sharpens the edge of the ski or snowboard, and puts structure (think treads in a tire) in the ski or snowboard. We work through a series of belts to flatten and make your equipment smooth. From there, we side edge your ride to sharpen the edges. This allows for a smooth, predictable and consistent ride.If the customer upgrade to the performance tune we will run the skis or snowboard over the stone and add structure to the ski. This machine is the work horse of the shop; it's responsible for the majority of the evo tunes. | We use this for a “higher end” edge finish. It’s a ceramic disc that will cut/polish the edge to the precise bevel set by the technician. This is considered a finish machine and is used to make a remarkably sharp smooth edge after the base of the ski has been flattened with the stone…your skis or snowboards will cut through the snow and ice like a hot butter knife and give you incredible edge hold. |

| |

| The Polyman is used to fill all the minor and major scratches in the bases of ski/snowboards. We can fill with black or clear P-Tex to make the flaw blend in with your base. This gun melts the P-Tex at just the right temperature so it will hold up to the elements. We use it to fill anything from core shots to small scratches so we don't have to grind the base of the equipment as much, which will preserve the life of your gear. | We use this to test the function of a ski binding after we have mounted or adjusted a binding. Every binding that we work is run through this machine so we can ensure it is functioning as designed and certified for your safety. |

| |

| Used to make sure all the new boards go out the door with a fresh coat of wax. For normal hot waxes and tunes, we hand hot-wax with an iron and scrape it, giving each ski and snowboard a personal touch for the best quality ride. | |

Ski Mounting & Snowboard Mounting:

| Standard Ski Mounting 0/3 | $55.00 | Pricing if no items (ski, boot, binding) purchased at evo. Measure and mark mount location, set jig, drill ski, add glue in holes, mount bindings, adjust forward pressure, set DIN, function test binding, belt wax |

| Standard Ski Mounting 1/3 | $40.00 | Pricing if one of three items (ski, boot, binding) purchased at evo. Measure and mark mount location, set jig, drill ski, add glue in holes, mount bindings, adjust forward pressure, set DIN, function test binding, belt wax |

| Standard Ski Mounting 2/3 | $25.00 | Pricing if two of three items (ski, boot, binding) purchased at evo. Measure and mark mount location, set jig, drill ski, add glue in holes, mount bindings, adjust forward pressure, set DIN, function test binding, belt wax |

| Standard Ski Mounting 3/3 | FREE | Pricing if all three items (ski, boot, binding) purchased at evo. Measure and mark mount location, set jig, drill ski, add glue in holes, mount bindings, adjust forward pressure, set DIN, function test binding, belt wax |

| Re-Mounting | $65.00 | Glue and plug old holes, determine best mounting location, set jig, drill ski, add glue in holes, mount bindings, adjust forward pressure, set DIN, function test bindings, belt wax |

| Binding Adjustment & Test | $30.00 | Adjust binding to the boot, set DIN, perform function test, belt wax |

| Standard Snowboard Mounting | $30.00 | Mount bindings to board and adjust straps |

Ski Tuning & Snowboard Tuning:

| Edge & Wax | $30.00 | Side edge, detune, hand wax, and scrape |

| Hot Wax | $20.00 | Hand wax the ski or snowboard, scrape extra wax off, polish base |

| Basic | $50.00 | Belt grind base, side edge, hand wax and scrape |

| Deluxe | $60.00 | Minor P-Tex, belt grind base, side edge, hand wax and scrape. |

| Performance | $80.00 | Minor P-Tex, belt grind base, side edge, stone grind finish structure, ceramic edge finish, hand wax and scrape |

Backcountry:

| Skin Trim | $40.00 | Cut the skins to match the ski profile, and attach tip and clips if needed |

| Splitboard Binding Mount | $50.00 | Mount binding pucks to rider's stance angles and width, install tour mode and heel risers, adjust binding to fit boot |

Repairs:

| P-Tex | $10.00 | Starts at $10 |

| Core Shot/Base Weld | $10.00 | Starts at $10 |

| Edge Repair | Estimate Only | |

| Base Patch | Estimate Only | |

| Epoxy Work | $20.00 | Starting at $20 |

| Hourly Shop Rate | $80.00 |

Terms Explanation:

|